Gas detection inside underground car parks

Inside closed spaces such as underground car parks, the presence of a large number of vehicles with different types of engines and fuels can give rise to concentrations of toxic gases , such as carbon monoxide (CO), well above the threshold of concern.

Monitoring the concentration of toxic gases in an enclosed space such as an underground car park is necessary for two main reasons:

- Health hazard : carbon monoxide (CO) is an odorless and colorless gas generated by the combustion of fossil fuels such as petrol and diesel and, if not controlled, can have extremely dangerous effects for people and animals. A high concentration of CO can in fact cause headaches, fatigue, nausea, and even death in extreme cases.

- Energy efficiency : ventilation systems are often used in underground car parks to reduce the concentration of harmful gases. However, continuously operating these devices can lead to higher energy and maintenance costs .

The installation of a gas detection system capable of monitor the CO concentration in real time (and/or other toxic gases) and of consequently activating countermeasures such as ventilation and extraction systems, as well as alarms if necessary, translates into greater safety and energy efficiency of the structure.

Depending on the state in which the monitoring system is installed, there may be different obligations or recommendations regarding the levels of attention or alarm on monoxide.

Some bodies/codes that have expressed levels of concern for Carbon Monoxide are: OSHA, NIOSH, ACGIH, International Mechanical Code.

While referring to the provisions of each of these documents, here is an example of setting security levels that could be implemented within an underground car park:

- Pre-alarm : 25ppm. Activation of the first stage of the ventilation system

- Alarm 1 : 50 ppm. Second stage activation of the ventilation system.

- Alarm 2 : 100 ppm. Third stage activation of the ventilation system and signaling of the state of attention to the control personnel with acoustic and visual systems.

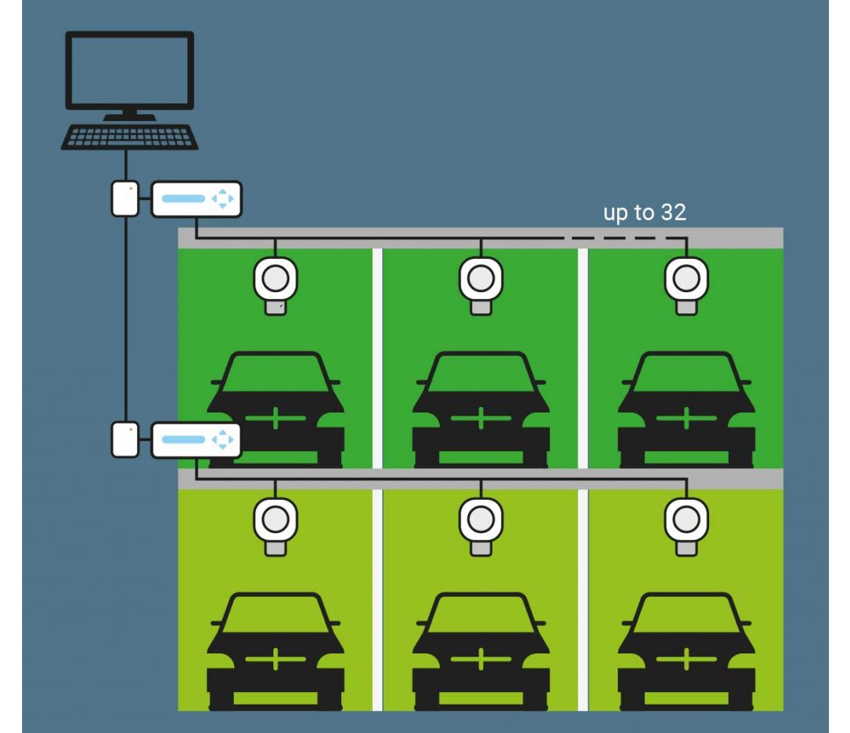

The detection system proposed by Seitron is made up of a set of gas concentration transmitters connected to each other via a RS485 field bus and Modbus® RTU protocol , which communicate with a control unit (RYK01M) which has relays activated by the individual thresholds alarm, as well as some auxiliary relays for customized functions.

Naturally, the strategic positioning of the transmitters depends on contingent factors of the place in which the system is located and may also include the use of ATEX transmitters .

To give surveillance personnel the opportunity to control the state of the system, as well as intervene to modify the activation thresholds, a Modbus®/Modbus® gateway (ACIMB2) is available which relays the state of the bus to a supervisory device which can be a simple desktop PC or a BMS system, possibly based on a PLC.

Up to 32 transmitters sensitive to various types of gas can be connected to the RYK01M control unit based on the needs of the structure, from NO2 to CH4 , from LPG to petrol vapors .

Furthermore, the management software allows you to control multiple control units at the same time, allowing you to expand the areas to be monitored as you wish (such as the floors of an underground car park).

Do you need a clear and ready-to-use overview of the RYK01M system? We have summarized all the scalability and integration features in a handy PDF guide.