Emissions analysis in a cement plant

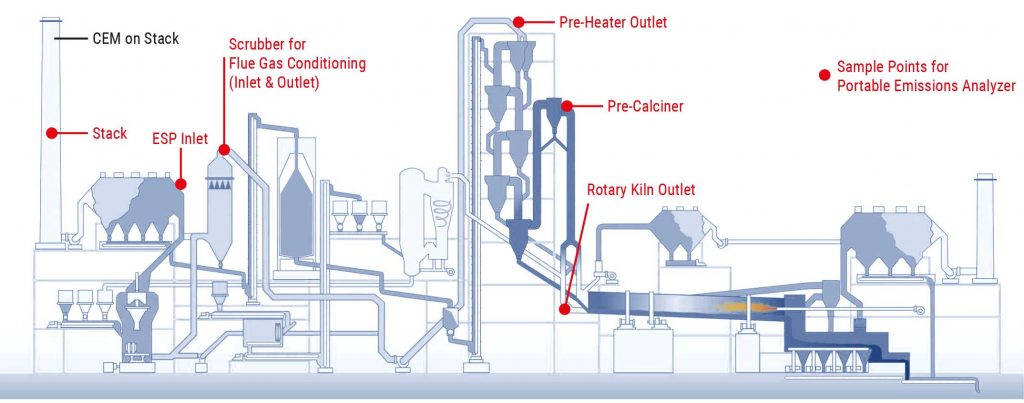

There are many points within a cement plant that should be monitored and measured with a portable gas emissions analyzer to maximize product quality, combustion efficiency, safety and emissions reduction.

The importance of a portable emissions analyzer

Despite a CEM (Continuous Emission Monitor similar to our S9000-RACK) being necessary to monitor the gases in the main chimney to ensure regulatory compliance with EPA regulations, the use of a portable analyzer with a high temperature probe is essential for measuring the parameters that significantly affects the production process along with the quality of the product, the efficiency of the kiln’s combustion and the emissions generated at various points of the system.

Here a list of the parameters that has to be measured in a cement plant:

- Rotary kiln gas outlet: O₂, CO, NOx, CO₂, SO₂, CxHy, temperature

- Pre-heater & Pre-calcination kiln: O₂, CO, NOx, CO₂, temperature

- Exhaust gas conditioning system: CO, NOx, SO₂ and CO₂

- Electrostatic Precipitator (ESP): CO

- Main chimney: O₂, CO, NOx, CO₂, SO₂ and CxHy

Seitron instrumental solution

Seitron offers two solutions – the S9000-Rack for continuous analysis and the S9000 as a portable analyzer.

Indeed, the S9000 can even be set up as a kit suitable for use in cement factories thanks to the provision of a high-temperature sampling probe, specific cement dust filters for the sampling, a built-in gas cooling system and accurate measurement of O₂, CO, CO₂ and both NO and NO₂ for the calculation of the total NOx, SO₂ and CxHy.

Are you interested to know more? Contact us!

Download the full pdf version: Emissions analysis in a cement plant