Optimization and safety in industrial engines

There are many types of industrial internal combustion engines, both stationary and mobile, that can run on gas or diesel. Engines can even run on lean combustion with a high AFR (Air to Fuel Ratio) or rich combustion with a low AFR.

Emissions monitoring: why is it necessary?

Combustion exhausts contain polluting gases such as CO, NO, NO₂, NOx and potentially high levels of combustible hydrocarbons, along with particulate matter. Measuring these emissions is fundamental for several reasons.

Performance and safety

Emissions analysis helps fine tuning the combustion process, thus increasing performance and safety.

Environment regulations

Monitoring processes allows user to find potential needed adjustments to follow important emissions regulations.

The importance of O2 measurement

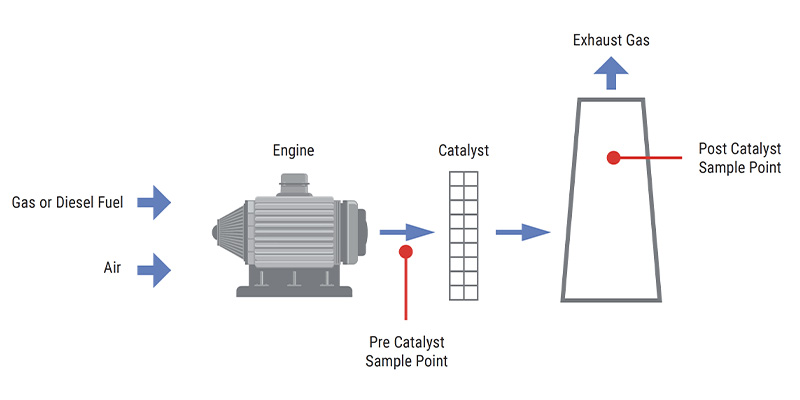

Measuring the O₂ and CO levels immediately after the combustion process and before the gases reach the catalyst converter gives an idea of just how lean or rich the combustion is. This value can be utilized to fine-tune the process and optimize performance and safety.

Another reason to measure the O2 level of the post-catalyst exhaust gas is that most emissions reporting must be done for a given reference level of O2. The typical O2 reference level for engines is 11% to 15% (contact your local environmental authorities for value in your area).

The role of CxHy, CO, NOx

Engine emissions (CO, NOx) are most often reported in units of parts per million (ppm) and grams per brake horsepower hour (g/bhp-hr). Emissions in ppm units can be converted to g/bhp-hr as a function of the thermal efficiency rating of the engine.

Significant levels of CxHy hydrocarbons over recommended limits are indicative of excess fuel, underlining the need for further adjustment to solve a problem with a high-risk potential, especially in engines using natural gas.

It must be considered that the presence of large concentrations of CO, NOx or hydrocarbons in the chimneys means dangers for both health and safety, hence why such are regulated by national laws.

Product solution

In order to perform the described measurements Seitron offers three portable emissions analyzers: Novo (up to 4 gases), S6000 (up to 6 gases), S9000 (up to 12 gases). These analyzers can all be equipped with O2, CO, NO and NO2 sensors, and are capable of measuring the total CxHy and NOx (NO+NO2), amongst others.

Are you interested to know more? Contact us!

Download the full pdf version: Optimization and safety in industrial engines