Testing the efficiency of NOx reduction

Most power stations use NOx reduction systems (such as ammonia injection, SCR, etc.) in the boilers to ensure that the emissions of such gases remain within the limits set by the environmental regulations in force.

Why Checking De-NOx processes

Frequent checking of the De-NOx process is essential in power plants so as to identify the operations necessary to ensure optimal performance and compliance with the environmental regulations.

PERFORMANCE AND SAFETY

Emissions analysis helps fine tuning the combustion process, thus increasing performance and safety, while optimizing cost savings.

ENVIRONMENT REGULATIONS

Monitoring processes allows user to find needed adjustments to follow important emissions regulations.

Importance of portable NOx analyzers

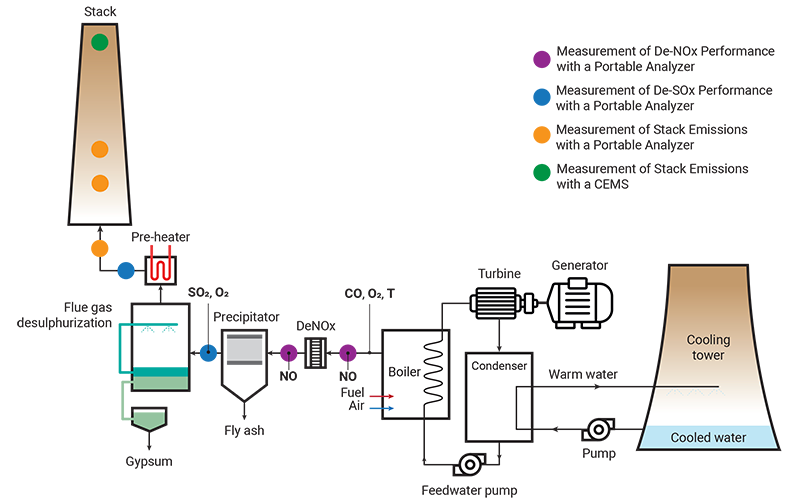

A common practice is to utilize CEMS (Continuous Emissions Monitors) in the stack to assess the totality of emissions released continously 24/7/365. However, this information alone is not enough for identifying any specific malfunction in the NOx reduction system or where to identify where the issues are.

To overcome this problem, it is necessary to use a portable emissions analyzer for NOx. Thanks to this instrument, it is actually possible to conduct various analyses along the entire combustion process, thus including before and after the application of the anti-NOx systems in place, which allows the users to optimize the reduction of these gases.

Product solution for testing De-NOx processes

The S6000 or Novo Portable NOx Emission Analyser is the ideal solution for assessing the gases emitted by industrial boilers in power plants. The S6000 can be equipped with up to 6 gas sensors, in accordance with client requirements, whereas Novo can be equipped with up to 4 gas sensors.