Optimization of a cogeneration plant

Cogeneration is the process of simultaneously producing electricity and heat through the concurrent utilization of turbines, engines, boilers or other instruments. The energy and heat generated can be used for heat, steam, and/or for production-industrial processes.

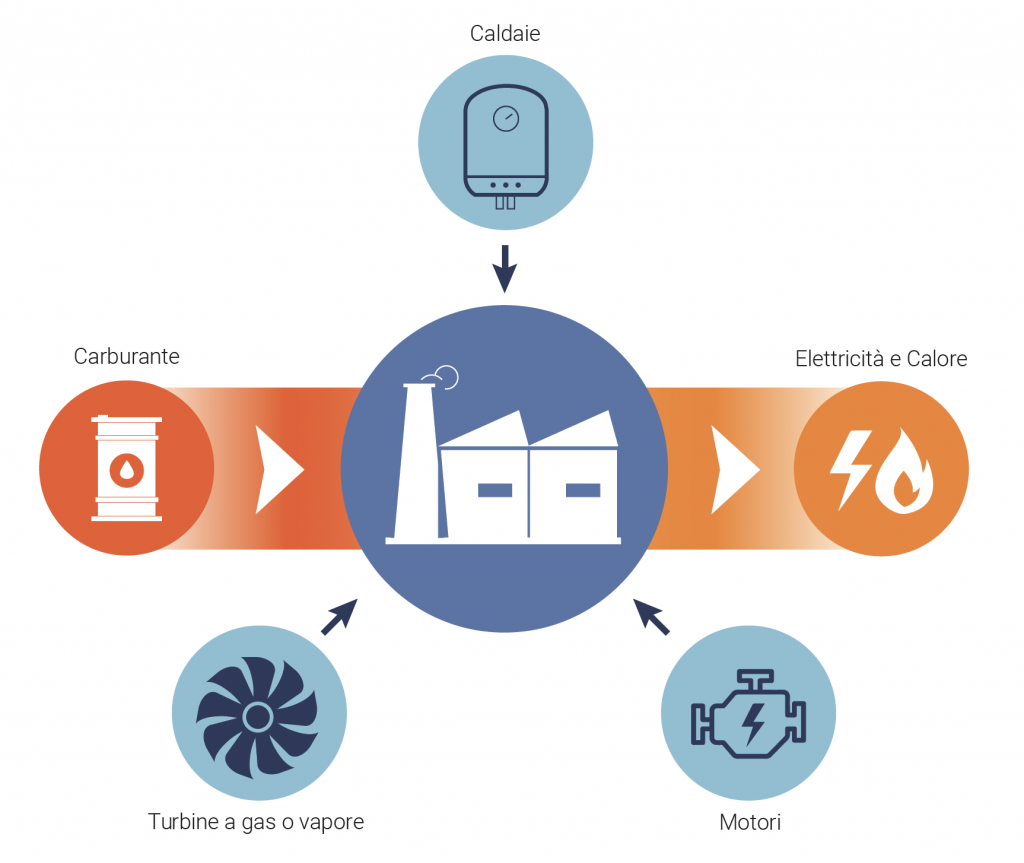

The principle of cogeneration

Here a diagram showing the principle behind a cogeneration plant.

Some examples of applications of the cogeneration process include power plants, refineries, chemical plants, food and pharmaceutical companies, incinerators, paper mills, sugar refineries, sawmills, institutions (schools, hospitals, prisons, college campuses) and plants powered by peat and wood waste.

How to optimize a cogeneration plant

To maximize the yield of such plants, it is obviously necessary to monitor fuel consumption, combustion efficiency and the level of emissions.

These checks are also essential for the maintenance and safety of the plant and can be carried out with emissions gas analyzers that permit verification of the temperature of the gases and their concentrations. In particular, the gases concerned are O₂, CO and CO₂, CxHy, total NOx (NO + NO₂), SO₂ and H₂S (amongst others).

Our Solution

The solution proposed by Seitron is the Chemist 900, capable of carrying out accurate measurements of the gases in question and equipped with dedicated software for data recording and analyses.