The art of sampling and monitoring emissions

In this Application Note, we shall see the guidelines regarding correctly performing gas sampling for emissions monitoring in industrial and civil systems through the use of combustion and emission analyzers.

Introduction

Accurate monitoring of emissions in industrial processes is a central aspect for evaluating the efficiency of the combustion system, along with its safety and compliance with environmental regulations. However, emissions are not all the same. Indeed, each system has its own characteristics that must be taken into account when selecting the tools to be utilized. The art of sampling and monitoring emissions thus requires:

- Knowledge of your application

- An assessment of the objectives to be achieved

- Having the accessories and specific safeguards for the system/machinery to be monitored

Once the monitoring criteria have been identified, a strategy can be implemented that applies to the objectives defined .

Application considerations

Before proceeding with the analysis, it is necessary to ask some questions able to assist us to determine the correct instrument and its setup.

What gases need to be monitored? For example, O2, CO, NO, NO₂, SO₂, CO₂, HC, H₂S, NH3, and CH4 can be included.

What are the ranges for the individual gases? Are they high or low ranges? Answering this question determines the type of sensor that will be needed.

Will you have to monitor water-soluble gases such as NO2 or SO2? If the answer is yes, then you will need to use dehumidification systems such as a Peltier module condensation assembly, sample conditioning unit, or chiller.

What temperatures are reached in the system? Gases at high temperatures require the use of specific probes and moisture removal systems.

Is there a significant amount of dust/particulate/ash in the extracted gas? If so, it will be necessary to use probes with special filters to remove any matter that could compromise the integrity of the gas sample, the life of the sensors and the reliability of the analysis in general.

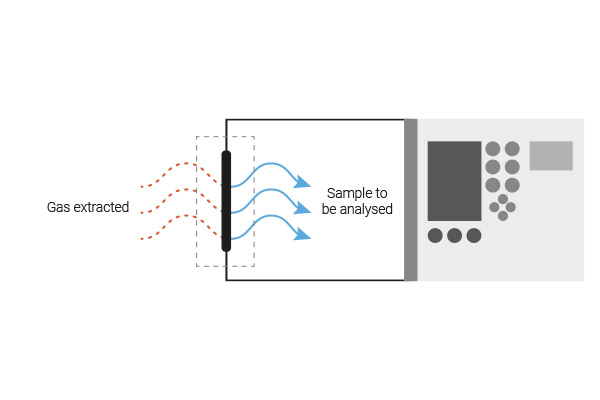

Understanding the gas sampling mechanism

Maintaining gas integrity is critical to ensuring an accurate measurement of emissions but learning the correct sampling technique is also vital for a successful analysis. Let’s look at the sampling mechanism divided into five crucial steps.

A. Criteria for using the probe

The criteria for the optimal selection of the probe must take into account the following points:

- Adequacy of the probe. It is necessary to have a probe suited to the type of application on which the sampling is to be conducted. For example, if we are dealing with high temperatures, we will have to opt for a specific probe able to withstand the temperatures required. The strong presence of particulates, rather, will require the use of filters for the probes.

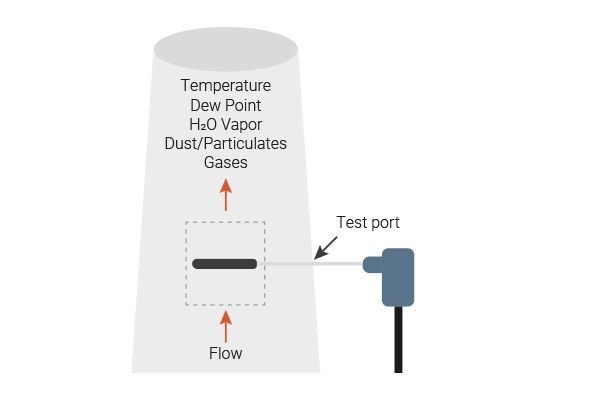

- Length and location of the probe. The position of the sampling will ideally be at least 8 chimney diameters from the previous disturbance and at least 2 chimney diameters from the exhaust vent, or as far away as possible from any disturbances. The length of the probe must be chosen based on the diameter of the chimney, with the tip of the probe to be positioned as central as possible within the chimney and far from its walls.

B. Adequacy of the seal

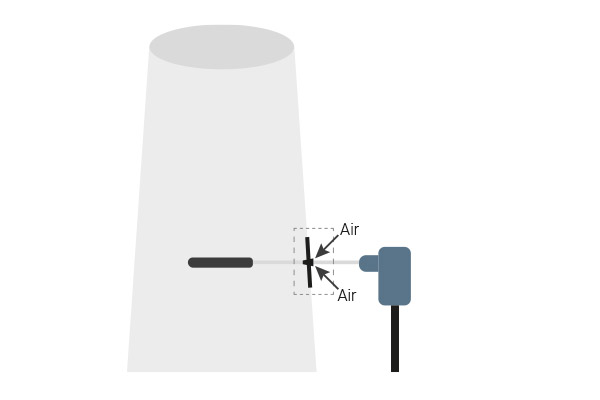

The inspection point where the probe is to be introduced must be large enough to permit entry of the probe itself and of the filter, if used. The area between the probe and the inspection door must be properly sealed. In the event of positive pressure, this serves to prevent gas leaking out, which could endanger the operator’s safety. If there is a negative pressure, the seal serves to prevent the entry of air into the chimney and the consequent dilution of the sampled gas. Thus the importance of the included positioning cone as well.

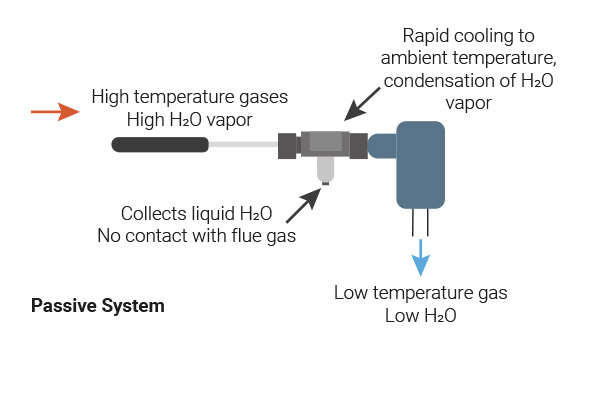

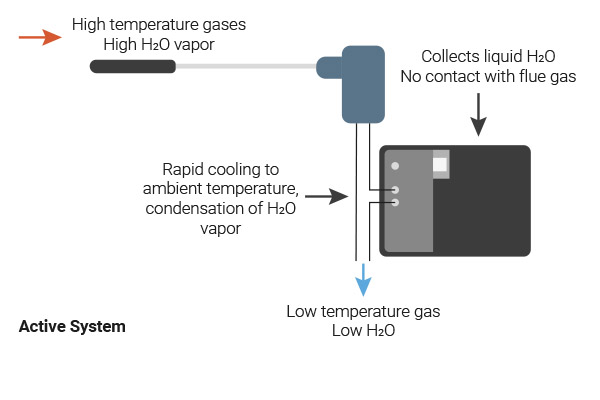

C. Dehumidification/Moisture Removal system

Moisture within a sample can interfere with the accuracy of the measurement, depending on the types of gas to be measured. Highly soluble gases such as NO₂ and SO₂ may be diluted during sampling and thus result in lower concentrations than they actually are.

It is thus recommended to use dehumidification systems, such as a Peltier module condensation assembly, in order to guarantee the integrity of the gas sample before it reaches the sensors. This step is necessary in order to be sure of carrying out an accurate detection of soluble gas concentrations and thus to be certain of compliance with the emission limits set by legislation.

D. Standard or heated sampling tube

The standard sampling tube that pulls the gases from the probe to the analyzer is constructed of materials that do not react with the components of the sampled gas and must be sufficiently repels moisture from the sample.

In the event that very low concentrations of NO₂ and/or SO₂ must be measured, or if a tube longer than 6 meters is required, it is necessary to use the heated sampling tube, which minimizes the possibility of gas condensing within the tube.

E. Additional protection against humidity and dust

A good analyzer must include a powerful sampling pump to provide minimal gas residence time in the sampling hose and quick measurements. Another important device is the cooler that not only cools but also dries the gas sample as it enters the analyzer. A system of replaceable internal filters and a condensation trap is also necessary to remove any residual dust and moisture from the sample. This ensures the accuracy of the analysis and extends the life of the sensors .

Solutions for accurate monitoring and sampling

In industrial applications, the most comprehensive Seitron analyzer – able to be configured to meet the broadest range of analysis needs – is the Chemist 900.

This portable analyzer can measure up to 12 gases, including O₂, CO, CO₂, NOx (NO + NO₂), NH3, SO₂, H₂S and CxHy. It can even be equipped with an additional NDIR bench for analyzing 3 gases.

The Chemist 900 can also be fitted with a Peltier module condensation assembly to dehumidify and purify gases for a more accurate analysis of water-soluble gases, such as SO₂ and NO₂.

It is possible to use probes with a heated head and/or heated tube. The gas sample is then stripped of moisture and impurities by means of the condensate trap and filter within the device.

If you need continuos measurements, then our solution is Chemist 900 Rack, which features the same characteristics of the Chemist 900, but can measure up to 9 gases.

Seitron offers two other portable emissions analyzers, which can be used in industrial application, when you have less gases to analyze:

- Chemist 600 it’s a compact, hand-held instrument, which can measure up to 6 different gases, which can be customized based on the type of application.

- Novo is our newest analyzer. It features a 7’’ touch screen, dedicated probe with one simple connection, integrated water trap, simultaneous measurement of gas pressure and combustion results, dual range sensor technology. Novo can measure up to 4 gases.